Innovations with ARC Nonwoven Fabric in Multiple Sectors

Explore the various implementations of ARC Nonwoven Fabric across different sectors. Learn how these innovations are revolutionizing industry norms.

Read More

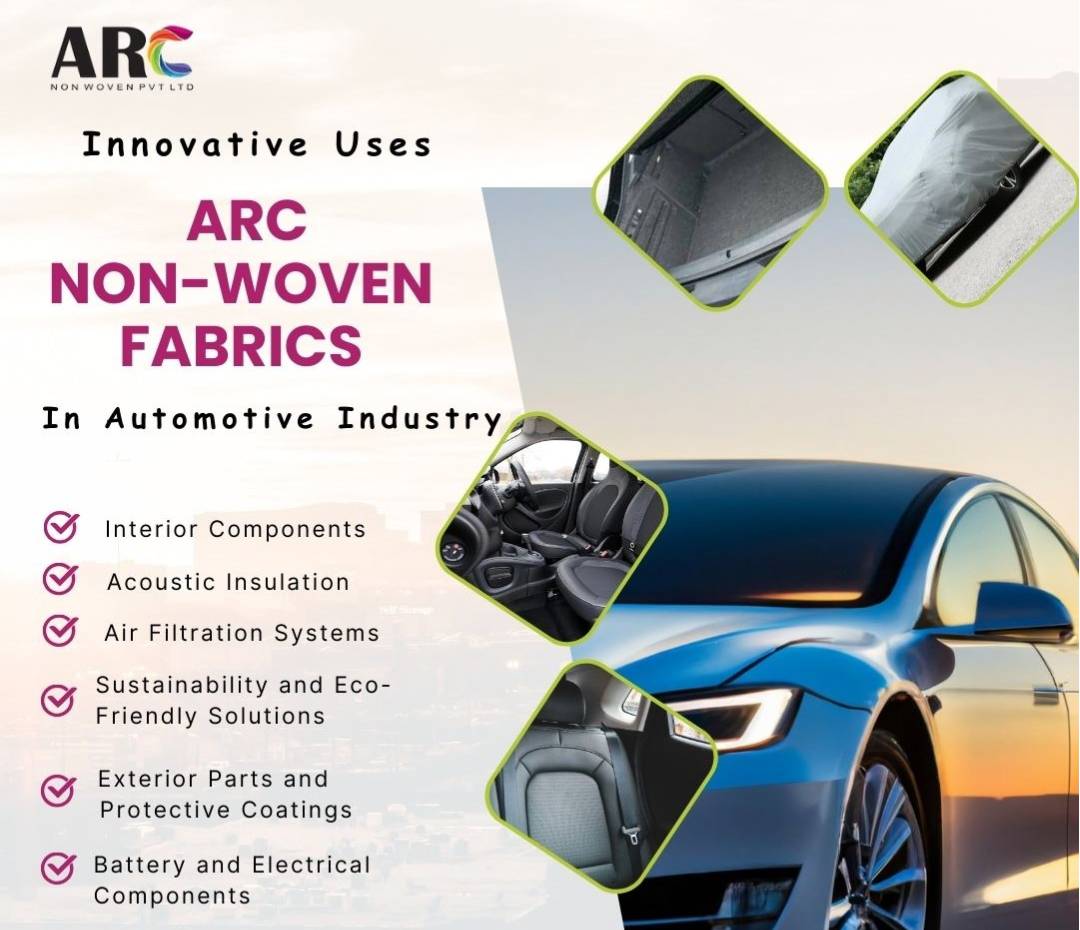

The auto world is changing fast. Cars are lighter, safer, and better for the environment. This shift is driven by new materials that make vehicles more efficient. Among these, non-woven fabric stand out. They are quietly transforming how cars are built, offering big benefits in performance and sustainability.

Non-woven fabric are materials made from fibers bonded together without weaving or knitting. They are created through processes like spun bond, melt blown, or needle punch. These methods produce fabric that are strong yet lightweight. They can be flexible or stiff, depending on their use.

What makes non-woven fabric special? They are durable, cost-effective, and easily recycled. Their lightweight nature helps reduce overall vehicle weight, which improves fuel economy. Plus, they can be tailored for various functions, from insulation to filtration.

The auto industry is adopting non-woven fabric faster than ever. Statistics show that their usage in vehicle parts has doubled in recent years. Major automakers, like Ford, Toyota, and Volkswagen, now include non-woven materials in many models. These companies see the benefits in reducing costs and improving vehicle performance.

Several factors drive this trend:

These reasons push automakers to explore non-woven fabric for a wide range of parts and systems.

Non-woven fabric can be recycled easily. They support a circular economy by allowing materials to be reused. Some manufacturers now source fibers from bio-based or recycled plastics, making their production greener.

Using non-woven fabric cuts raw material costs. They simplify assembly by offering flexible, easy-to-handle materials. Lighter vehicles consume less fuel, saving owners money over time.

Non-woven fabric meet or exceed global standards for safety, emissions, and recyclability. Certifications like OEKO-TEX and ISO standards confirm their quality and Eco-friendliness.

Ensuring consistent quality and durability can be tricky. As vehicles become more sophisticated, so must the fabric. Recyclability at end-of-life remains a challenge that researchers are actively tackling.

Research is pushing toward biodegradable, plant-based non-woven fabric. These offer the promise of even cleaner, greener options. Future fabric might include embedded sensors or UV protection, making cars smarter and safer.

The global market for automotive non-woven fabric is expected to grow significantly over the next decade. Electric and autonomous vehicles open new possibilities, like adaptable interior fabric that can change color or function.

Non-woven fabric are reshaping the auto industry in a quiet but powerful way. They help make vehicles lighter, safer, and more Eco-friendly. Their versatility allows automakers to cut costs while meeting tough safety standards. As technology advances, expect these fabric to play an even bigger role in creating smarter, greener cars. If you’re in the automotive world, investing in non-woven fabric innovations promises a future where safety, sustainability, and affordability go hand in hand.

Explore the various implementations of ARC Nonwoven Fabric across different sectors. Learn how these innovations are revolutionizing industry norms.

Read More

Discover how Arc Non-Woven Fabric are revolutionizing the textile manufacturing industry. Dive deep into the role it plays in the modern textile world.

Read More© Copyright 2020-2025 All Rights Reserved By ARC Non Woven Pvt. Ltd.